Bitumen Pastillator

Home » Pastillator Machine » Bitumen Pastillator

IPG Bitumen Pastillator

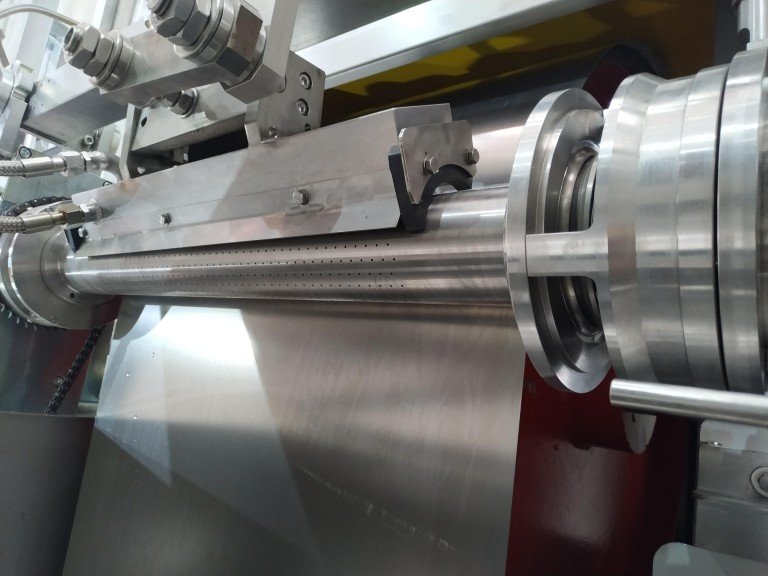

The Bitumen Pastillator by IPG is an industrial-grade solution engineered to transform molten bitumen into solid hemispheric pastilles with precision and efficiency. Designed for large-scale operations, this advanced machine ensures easy handling, improved storage, and safer transportation of bitumen—widely used in industries such as road construction, waterproofing, and more. From its high-performance design to its safety-focused automation features, the Bitumen Pastillator stands out as a modern solution for industrial granulation needs.In addition to the asphalt range, we also offer other Pastillator plants.

Key Features

High Performance: Produces uniform, high-quality pellets/pastilles for reliable industrial applications, backed by expertise from a leading Pastillator Machine Supplier.

Steel Belt Cooling Technology: Features a continuously moving steel belt paired with water cooling underneath to ensure rapid and precise solidification, leading to evenly formed pellets.

Versatile Processing: Handles various types of bitumen, including modified bitumen, ensuring adaptability to any project or material-specific requirement.

Enhanced Safety and Automation: Built with explosion-proof technology and automated controls to minimize manual intervention and bolster workplace safety.

Technical Specifications

Capacity Options: Models available with capacities ranging from 100kg/h to 1200kg/h

Steel Belt Widths: Options include 600mm, 1000mm, 1200mm, and 1500mm for diverse operational needs.

Power Efficiency: Optimized power ranging from 1.5kW to 7.5kW ensures energy-efficient operations.

Dimensions and Weight: Compact yet robust with a length of approximately 18.2 meters and weights depending on model specifications (~1500–9000kg).

Temperature Tolerance: Capable of handling molten materials up to 300°C with ease.

Applications

The Bitumen Pastillator is ideal for bitumen pellet production, catering to industries such as:

Road Construction: Ensures easy handling and storage of bitumen pellets for asphalt paving.

Waterproofing Solutions: Offers refined pelletized bitumen for applications requiring precision.

Industrial Manufacturing: Supports efficient processing of modified and high-viscosity bitumen types.

Benefits

Efficiency and Consistency: Streamlined production minimizes downtime and ensures uniform pellet quality.

Enhanced Safety Measures: Explosion-proof designs and automation prioritize operator safety.

Eco-Friendly Features: Designed to reduce waste during the bitumen solidification process, contributing to sustainability.

Ease of Transportation and Storage: Converting molten bitumen to pellets decreases challenges, making logistics simpler and cost-effective.