IPG’ve often been asked: Can the right plastic material really make or break a product’s performance? The answer lies in understanding the nuances between polyethylene and polypropylene, two of the most widely used plastic materials in modern manufacturing.

Both polyethylene and polypropylene are preferred across various industries for their durability and versatility. However, their distinct properties make each suitable for different applications. In this comprehensive guide, I’ll delve into the chemical structures, physical properties, and practical uses of these materials, helping you make informed decisions in your industrial applications.

Understanding Polyolefin Plastics

In my experience at IPG, designing and manufacturing pelletizing machines has given me a deep understanding of polyolefin plastics, which are a crucial family of thermoplastic polymers that include both polyethylene and polypropylene.

Semi-crystalline plastics, like polyethylene and polypropylene, have a highly organized molecular structure. This unique arrangement gives them specific properties, including remaining relatively stable below their melting point. However, once they reach this point, they transition into a liquid almost instantaneously. This characteristic is crucial for understanding their behavior in various applications, including processing in industrial equipment like the pelletizing machines we manufacture.

| Property | Semi-Crystalline Thermoplastics |

| Molecular Structure | Highly Organized |

| Behavior Below Melting Point | Remains Stable |

| Transition at Melting Point | Almost Instantaneous |

Polyolefins are formed through the polymerization of olefin monomers, also known as alkenes. For polyethylene, the monomer is ethylene, while for polypropylene, it is propylene. During polymerization, these monomers link together to form the respective polymer. This process is fundamental to understanding the properties and applications of these plastic materials.

Understanding the chemistry and properties of polyolefins is essential for optimizing the design of pelletizing machines for different plastic types. At IPG, this knowledge helps us improve our manufacturing processes, ensuring high-quality output for our clients.

What Is the Difference Between Polyethylene and Polypropylene?

At IPG, we often get asked about the differences between polyethylene and polypropylene, and it’s a question that gets to the heart of material selection. As an industrial equipment manufacturer specializing in pelletizing machines for plastics, understanding these differences is crucial for our operations and for advising our clients on the best materials for their needs.

Chemical Structure Comparison

The chemical structure of polyethylene and polypropylene differs significantly due to the presence of a methyl group in polypropylene. This additional methyl group affects the properties of polypropylene, making it stiffer and more resistant to chemicals compared to polyethylene.

The chemical structure comparison can be summarized as follows:

| Material | Chemical Structure | Key Characteristics |

| Polyethylene | Linear or branched carbon chain | Inert, translucent, lower static charge |

| Polypropylene | Linear or branched carbon chain with an additional methyl group | Stiffer, more resistant to chemicals, higher melting point |

Physical Properties Comparison

Working with these materials, I’ve noticed significant physical property differences. Polyethylene is generally less dense and more flexible than polypropylene. On the other hand, polypropylene is stiffer and can handle higher temperatures, making it better for applications needing thermal resistance.

Here’s a comparison of their physical properties:

| Property | Polyethylene | Polypropylene |

| Density | Lower | Higher |

| Flexibility | More flexible | More rigid |

| Melting Point | Lower | Higher |

Performance Under Different Conditions

Polyethylene and polypropylene perform differently under various conditions. Polypropylene’s higher melting point is better for high-temperature uses. Meanwhile, polyethylene’s impact resistance at lower temperatures is ideal for certain cold applications.

Here’s how they perform under different conditions:

| Condition | Polyethylene | Polypropylene |

| High Temperature | Less suitable due to lower melting point | More suitable due to higher melting point |

| Low Temperature | Better impact resistance | Less impact resistant |

| Chemical Resistance | Less resistant | More resistant |

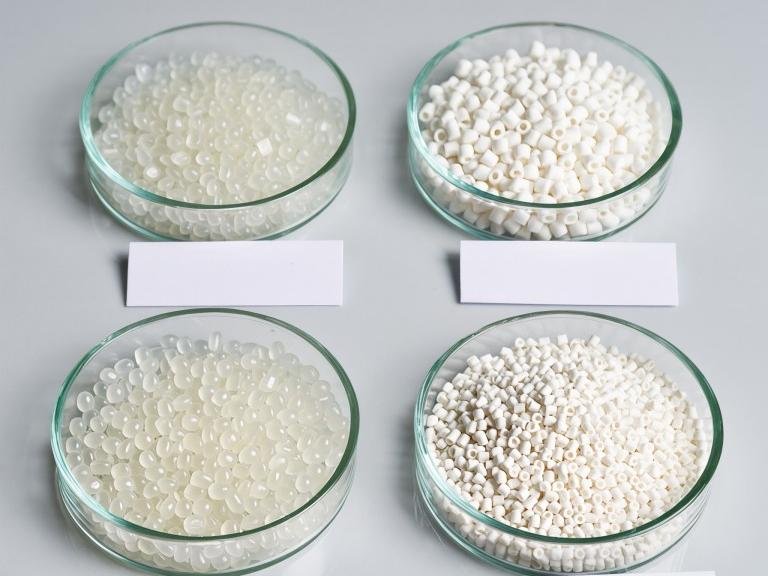

Polyethylene: Properties and Types

At IPG, we use polyethylene in our pelletizing machines. Knowing its properties is key for efficient processing. Polyethylene is versatile, used in many industrial applications due to its varied properties and types.

Low-Density Polyethylene (LDPE): LDPE is known for its flexibility and strength, making it great for plastic bags and packaging films. It’s also resistant to high temperatures, staying stable up to 185°F (85°C). Its transparency and water resistance make it perfect for packaging.

High-Density Polyethylene (HDPE): HDPE is a heavy-duty grade of polyethylene, known for its durability and chemical resistance. It resists corrosion and absorbs little moisture, ideal for containers, pipes, and packaging. HDPE is used for food containers, bottles for chemicals, and more, where its strength is beneficial.

Ultra-High Molecular Weight Polyethylene (UHMW): UHMW has extremely high impact resistance and self-lubricating properties. It’s valuable for machine parts and high-wear applications. Its durability makes it suitable for use inside machines, reducing wear and tear.

Polyethylene Terephthalate (PET): PET, also known as polyester, shares qualities with UHMW but has a slightly higher melting point and better dielectric properties. It’s used for packaging and containers for various materials. Its strength, transparency, and barrier properties make it ideal for beverage bottles and food packaging.

Understanding the different types of polyethylene and their properties helps us at IPG design better pelletizing equipment. Each type behaves differently during processing, requiring specific machine settings for optimal results.

Polypropylene: Characteristics and Advantages

As an industrial equipment manufacturer, I’ve witnessed the benefits polypropylene brings to various fields. At IPG, we focus on creating pelletizing machines for plastics. Our work with polypropylene has revealed its distinct advantages.

Polypropylene (PP) stands out as a semi-crystalline plastic for its toughness, chemical resistance, and low moisture absorption. Its high melting point, around 160°C, allows it to handle higher temperatures than polyethylene. This makes it suitable for a broad spectrum of uses.

Chemical Resistance Properties: Polypropylene is renowned for its exceptional chemical resistance. It can endure exposure to numerous solvents, acids, and bases. This makes it perfect for laboratory equipment and chemical containers. Its resistance to harsh chemicals is crucial in healthcare, chemical development, and pharmaceuticals.

Thermal and Mechanical Properties: The thermal and mechanical properties of polypropylene enhance its versatility. Its high melting point and mechanical strength enable it to perform well under stress and at high temperatures. Additionally, polypropylene‘s fatigue resistance and flexibility are ideal for applications needing repeated stress, like living hinges in packaging.

Processing Characteristics: In manufacturing settings, polypropylene‘s processing characteristics are noteworthy. During injection molding, polypropylene exhibits predictable behavior, facilitating efficient production. Its low moisture absorption ensures dimensional stability, making it valuable for electrical components. Moreover, the crystallization behavior of polypropylene impacts cooling times and cycle times in processing equipment, such as our pelletizing machines.

In conclusion, polypropylene‘s unique characteristics make it a preferred plastic in many industrial applications. Its chemical resistance, thermal and mechanical properties, and favorable processing characteristics position it as a versatile material for a wide range of uses.

Industrial Applications and Use Cases

As an industrial equipment manufacturer, we’ve seen how polyethylene and polypropylene are used across various industries. Their unique properties make them suitable for a wide range of applications, from packaging and construction to automotive and consumer goods.

Polyethylene Applications

Polyethylene is versatile and widely used in different industries. It’s commonly found in packaging materials like bags, films, and containers. In construction, HDPE is used for pipes and insulation due to its durability and resistance to chemicals.

In agriculture, polyethylene is used for greenhouse films and irrigation systems, improving crop yields and water management. Consumer products like bottles and toys also rely on polyethylene for its safety and durability.

Polypropylene Applications

Polypropylene is another highly versatile plastic, used extensively in the automotive industry for parts and components. Its heat resistance and chemical stability make it ideal for food containers and medical devices.

In the textile industry, polypropylene is used to make carpets, upholstery, and other fabrics. The material is heated and formed into fibers, which are then woven into various products. The food industry also relies on polypropylene for packaging, particularly for hot-fill applications and microwave-safe containers.

How We Use Both Materials in Our Pelletizing Machines

At IPG, we employ both polyethylene and polypropylene in our pelletizing machines. Understanding their processing characteristics is key to optimizing our equipment for various plastic types. This approach enhances efficiency and product quality for our customers.

Specific components in our machines benefit from the unique properties of each material. For instance, HDPE is used in parts that require high durability. Meanwhile, polypropylene is used in components that need to withstand high temperatures.

Our experience with both materials informs our support for the injection molding industry. By producing high-quality plastic pellets from polyethylene and polypropylene, we enable manufacturers to create a wide range of products. These include consumer goods and automotive parts.

Choosing Between Polyethylene and Polypropylene

The choice between polyethylene and polypropylene hinges on several factors. These include the required strength, moisture resistance, and temperature resistance. Understanding the unique properties of each plastic material is crucial for making informed decisions.

Polyethylene’s flexibility and impact resistance make it suitable for applications like bags and food containers. On the other hand, polypropylene’s high melting point and chemical resistance make it ideal for automotive parts and industrial applications. Our experience in manufacturing pelletizing machines has shown us how material selection affects processing parameters and final product quality.

Both polyethylene and polypropylene continue to evolve with new formulations and manufacturing techniques. This expansion of their potential applications is seen in industries from packaging to construction. When choosing between these plastics, it’s essential to consider factors like moisture resistance, strength, and cost. Additionally, considering sustainability and recyclability is crucial for making environmentally friendly choices.

At IPG, we design our pelletizing equipment to efficiently process both materials. This helps our customers achieve optimal results regardless of which polymer they choose. By understanding the characteristics of both polyethylene and polypropylene, businesses can make informed decisions. These decisions optimize product performance and cost-effectiveness.

FAQ

What are the main differences between polyethylene and polypropylene in terms of their chemical structure?

Polyethylene is made from ethylene monomers, while polypropylene is made from propylene monomers. This difference in monomer units affects their properties and applications.

How do the physical properties of polyethylene and polypropylene compare?

Polypropylene generally has a higher melting point and is more rigid than polyethylene. Polyethylene, on the other hand, is more flexible and has a lower density.

What are the typical applications of polyethylene?

Polyethylene is widely used in packaging, including plastic bags, containers, and bottles. It’s also used in piping and geomembranes due to its chemical resistance and durability.

What are the advantages of using polypropylene?

Polypropylene is known for its high melting point, chemical resistance, and impact resistance. It’s often used in automotive parts, medical devices, and household goods.

Can polyethylene and polypropylene be used for food packaging?

Yes, both polyethylene and polypropylene are used in food packaging due to their non-toxic and non-reactive properties. However, it’s essential to ensure that the specific grade and type of plastic are suitable for food contact.

How do polyethylene and polypropylene respond to different temperatures?

Polypropylene generally performs better at higher temperatures due to its higher melting point. Polyethylene, on the other hand, can become more brittle at lower temperatures.

Are polyethylene and polypropylene resistant to chemicals and solvents?

Both polyethylene and polypropylene exhibit strong chemical resistance. Yet, polypropylene stands out for its enhanced resistance to organic solvents. Nonetheless, exposure to specific acids and oxidizing agents can still impact both materials.