PE Grinding Pulverizer

Home » Plastic Crushing Machine » PE Grinding Pulverizer

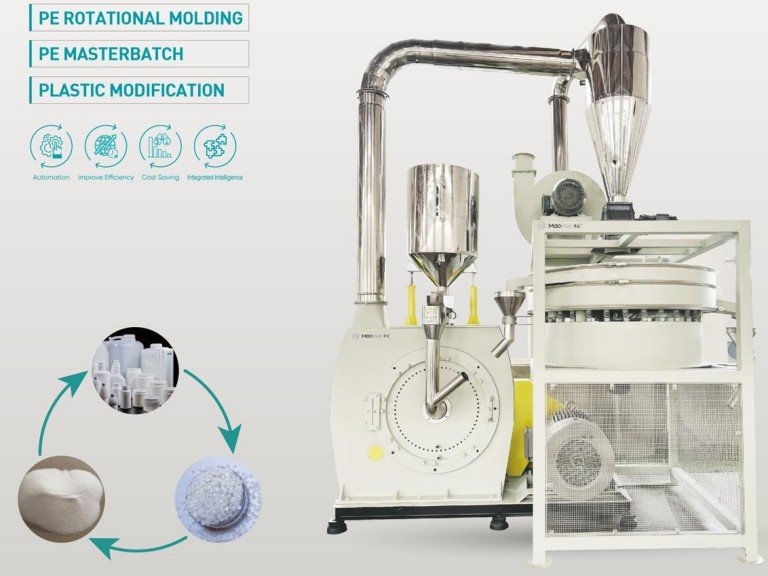

IPG PE Grinding Pulverizer

The IPG PE Grinding Pulverizer is the ultimate solution for transforming polyethylene, polypropylene, polystyrene, and ABS materials into fine powders. It meets the high demands of plastic manufacturers, recycling companies, and plastic processors. This machine combines performance and precision to optimize your operations across industries like rotational molding, masterbatch production, and plastic modification. In addition, we offer a variety of plastic crusher models to flexibly meet diverse production needs.

Technical Specifications

The PE Grinding Pulverizer is available in multiple models to suit varying production scales and requirements.

Parameter | Unit | MF-500 | MF-600 | MF-800 |

Disc Diameter | mm | 500 | 600 | 800 |

Dimension (Length * Width * Height) | mm | 2900*2900*3900 | 3000*3000*4000 | 3200*3100*4000 |

Main Motor | kW | 45-55 | 55-75 | 75-90 |

Fan | kW | 5.5 | 7.5 | 11 |

Vibrating Machine | kW | 1.1 | 1.5 | 1.5 |

Discharger Motor | kW | 0.75 | 1.5 | 2.2 |

Capacity | kg/h | 100-500 | 150-800 | 200-1200 |

Cooling Mode | – | Water, Air | Water, Air | Water, Air |

Plastic Finishing Size | mesh | 20-120 | 20-120 | 20-120 |

All models are equipped with wind and water double cooling systems, SKF bearings, and fine-tuned grinding gap adjusters for enhanced precision and reliable performance.

Key Features

High Output & Low Energy Consumption :Achieve exceptional powder processing efficiency while consuming minimal energy. This makes the pulverizer an ideal choice for cost-sensitive and high-volume requirements.

Durable Grinding Disc :Built with SKD11 material, the grinding disc offers unmatched durability and wear resistance, doubling the lifespan compared to standard options.

Advanced Cooling System :The main engine combines wind and water cooling mechanisms to prevent overheating, ensuring optimal performance during extended operations.

Why Choose the PE Grinding Pulverizer?

Dust-Free Operation :A fully sealed system prevents dust leakage, ensuring clean, safe processing, and a healthier working environment.

Fully Automatic System :The automated feeding, discharging, and screening processes streamline workflows and minimize manual intervention, allowing for maximum efficiency with minimal labor.

Customizable Mesh Sizes :Easily pulverize PE granules into powder with mesh sizes ranging from 20 to 120, tailored to meet your specific production needs.

Contact IPG For Quote!

Whether it’s for rotational molding, masterbatch production, or custom plastic modification, this mill delivers reliable results. It simplifies the challenge of producing high-quality powders from recycled plastics or virgin materials.

IPG designs its machines with reliability in mind, backed by an 8-year warranty, and offers comprehensive after-sales services, including installation and operator training, to maximize your productivity.

With a PE grinder from professional crusher machine manufacturer IPG, you are not just investing in a machine, you are investing in greater efficiency, lower operating costs and an environmentally sustainable production process.

Contact us today to learn how a PE Grinding Mill can take your plastic manufacturing or recycling business to the next level!