Twin Screw Dry Granulator

Home » Pelletizing Machine Plastic » Twin Screw Dry Granulator

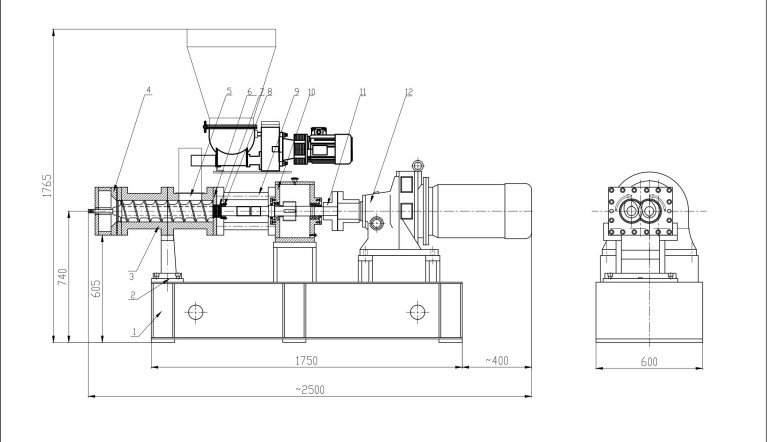

IPG Twin Screw Dry Granulator

IPG Twin Screw Dry Granulator combines efficiency, precision and flexibility to meet the stringent requirements of pharmaceutical companies, chemical manufacturers and industrial recyclers. Its advanced mechanical pressure technology produces high-purity granules without wetting agents, ensuring consistency and maintaining material integrity. As part of our comprehensive solutions, we also provide advanced pelletizing machine plastic designed to streamline the production of uniform pellets for various applications.

Technical Specifications

Model | Pressure roller center distance(mm) | Drive power(kw) |

DRG-240 | 240 | 7.5-15 |

DRG-360 | 360 | 22-45 |

DRG-460 | 460 | 37-60 |

DRG-520 | 520 | 45-90 |

DRG-600 | 600 | 55-200 |

DRG-800 | 800 | 90-315 |

DRG-1000 | 1000 | 160-560 |

Material Composition and Parameters for Dry Granulation Unit

Material | Composition | Parameter |

Antioxidant 110 | 40.70 ± 2% | 0.22 |

Antioxidant 168 | 40.70 ± 2% | 0.22 |

Zinc Stearate | 9.30 ± 1% | 0.05 |

HDPE | 9.30 ± 1% | 0.05 |

Product Features

Pellet Quality: PG Twin Screw Dry Granulator excels in producing high-strength granules with significantly higher specific gravity than traditional methods. This not only improves product quality, but also optimizes storage and transportation efficiency.

Efficiency and Versatility: The granulator has a short process and low energy consumption, achieving maximum output without compromising performance. Its continuous operation simplifies production efficiency, and its compact design saves valuable factory floor space. IPG Twin Screw Dry Granulator is also highly flexible, with hydraulic adjustment capabilities that allow you to adapt to a variety of materials and project requirements.

Specialized for Heat-Sensitive Materials: Low temperature operation makes this dry granulator ideal for processing heat-sensitive materials, maintaining product integrity while reducing the risk of degradation. Whether you’re handling pharmaceuticals, pigments, fertilizers or industrial dusts, this machine ensures reliable operation with every batch.

Easy Maintenance, Cleaner Workspace: IPG Twin Screw Dry Granulators are simple to clean and maintain, significantly reducing downtime and ensuring smooth operation. Plus, their dust-free granulation process improves workplace safety and minimizes exposure to hazardous particles, creating a healthier work environment for your team.

Cross-Industry Applications

From capsule filling granules and detergents to catalysts, fertilizers and industrial dust recovery, IPG Twin Screw Dry Granulators can handle a wide range of applications with precision. Its rugged design and advanced features make it your ideal partner as you scale up your production while maintaining your standards of excellence.

Contact IPG for a Quote

IPG Twin Screw Dry Granulators come in various models. They have different roller center distances and drive power options. These are designed for precision and versatility, making high-quality granules for industries like plastics, chemicals, and recycling.

IPG Dry Granulators make your production processes more efficient. They increase yields and make your work environment safer. Upgrade your operations today and see a big productivity improvement.

As a top Industrial Equipment Supplier, IPG offers advanced Dry Granulators. These boost your operational performance, ensuring consistent quality and sustainable outcomes.