PVC Cutter Grinding Pulverizer

Home » Plastic Crushing Machine » PVC Cutter Grinding Pulverizer

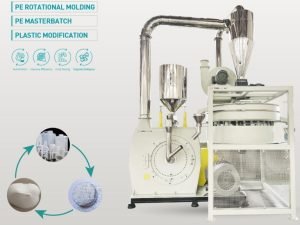

IPG PVC Cutter Grinding Pulverizer

The IPG PVC Cutter Grinding Pulverizer is a cutting-edge solution for seamless and efficient PVC recycling. Designed for recyclers and manufacturers, it provides precision grinding, maximized output, and minimal energy consumption. Whether processing PVC pipe, profiles, sheets, SPC floors, or bottles, this machine ensures high-quality results with an industry-leading output of up to 1,200 kg/h.

For more efficient plastic recycling, check out our range of plastic crusher machines for expert advice.

Technical Specifications

Parameter | Unit | MF-500 | MF-700 | MF-800 | MF-850 |

Millstone Diameter | mm | 470 | 660 | 660 | 660 |

Main Motor Power | kW | 45 | 55 | 75 | 90 |

Number of Strokes | – | 24 | 32 | 32 | 32 |

Suction Fan | kW | 4 | 5.5 | 7.5/11 | 11/15 |

Vibrating Screen Diameter | mm | 800 | 1000 | 1200 | 1500 |

Shut-off Fan Power | kW | 0.75 | 0.75 | 1.5 | 2.2 |

Output | kg | 120-280 | 160-450 | 300-800 | 700-1200 |

Dimension | mm | 2000*2000*3000 | 2700*2500*3900 | 2800*2600*3960 | 3000*2680*3980 |

Weight | kg | 1900 | 2000 | 2100 | 2300 |

Working Principle of the PVC Pulverizer

The PVC Pulverizer integrates advanced engineering with efficient workflows to achieve superior pulverization. Here’s how it works:

Raw Material Input: PVC materials like pipes or profiles are fed into the pulverizing chamber.

High-Speed Pulverization:Turbo-type blades rotate fast to grind the material into fine particles. You can adjust the blades to get particles between 15-120 mesh.

Cooling Measures:An airflow system keeps the material cool. A water mist system prevents clumping and keeps the material quality stable.

Separation & Collection:Pulverized PVC goes through a cyclone separator. This ensures precise separation and collection. The whole process is controlled by an electronic system for consistency.

The pulverizer’s cyclone and cooling system reduce thermal stress. This means longer equipment life and uniform powder output for various uses.

Key Components of the PVC Pulverizer

Vibrating Loader: Automates material feeding to optimize efficiency.

Pulverizing Disc:Turbo-type blade made from wear-resistant materials (D2, SKD-11). Offers adjustable blade settings for precise particle size control.

Stainless Steel Conveying Pipe:Crafted from 304 stainless steel; its robust, non-corrosive build ensures durability and clean operation.

Vibrating Screen:Enables automatic classification and grading of powders. Offers quick mesh size replacement for continuity in operation.

Intelligent Control System:Easily adjustable system ensures the pulverizer maintains ideal operational parameters with minimal manual intervention.

Dust Collectors:Available in standard bag types or optional pulse dust collectors, these systems ensure compliance with strict environmental standards while maintaining a clean workspace.

Outstanding Features and Benefits

Turbo-Type Blade Design:Ensures fast, efficient grinding with extended blade lifespan and minimal wear.

Adjustable Blades for Custom Particle Sizes:Get your desired powder size ranging from 20-120 mesh to fit various applications.

High Throughput at Lower Energy Costs:Handles outputs from 100 kg/h to an impressive 1,200 kg/h while maintaining low energy consumption with motor power between 45 kW and 90 kW.

Durable Build for Long-Term Performance:The pulverizer disc extends durability and minimizes replacement frequency, cutting lifetime costs.

Easy Maintenance Access:Simple door and blade access designs reduce downtime, allowing you to maximize your operational hours effortlessly.

Sealed Grinding System:Prevents dust leakage, optimizing workplace cleanliness and ensuring environmentally friendly operation.

Material Versatility:Suitable for processing PVC from pipes, profiles, bottles, and impact-resistant sheets, offering flexibility across all operations.

Efficient Cooling System:Advanced airflow and water mist technology reduce thermal stress, maintaining material quality while decreasing wear on components.

Applications

The PVC Cutter Grinding Pulverizer is ideal for a variety of applications, including:

PVC Pipes & Profiles:Efficiently pulverizes rigid PVC pipes and profiles into fine powders.

PVC Sheets:Transforms semi-rigid and brittle materials into uniform powders.

SPC Floors and Bottles:Processes impact-resistant PVC materials with minimal thermal stress, making it perfect for high-performance SPC flooring material.

Recycling Facilities:Optimized to convert post-consumer or post-industrial PVC waste into reusable powders with precise particle size control.

Why Choose the IPG PVC Cutter Grinding Pulverizer?

This pulverizer, crafted by a leading Industrial Equipment Manufacturer, IPG, lends innovative design with proven efficiency, making it a top choice for businesses aiming to enhance recycling and reduce costs. Its robust construction and advanced technology position it as a leader in PVC recycling.

Make your PVC recycling better and more efficient with our top-notch PVC Cutter Grinding Pulverizer.

See how it can boost your productivity and precision. Contact us for a consultation or to see it in action.